Sheet metal

Sheet metal stamping/bending/drilling

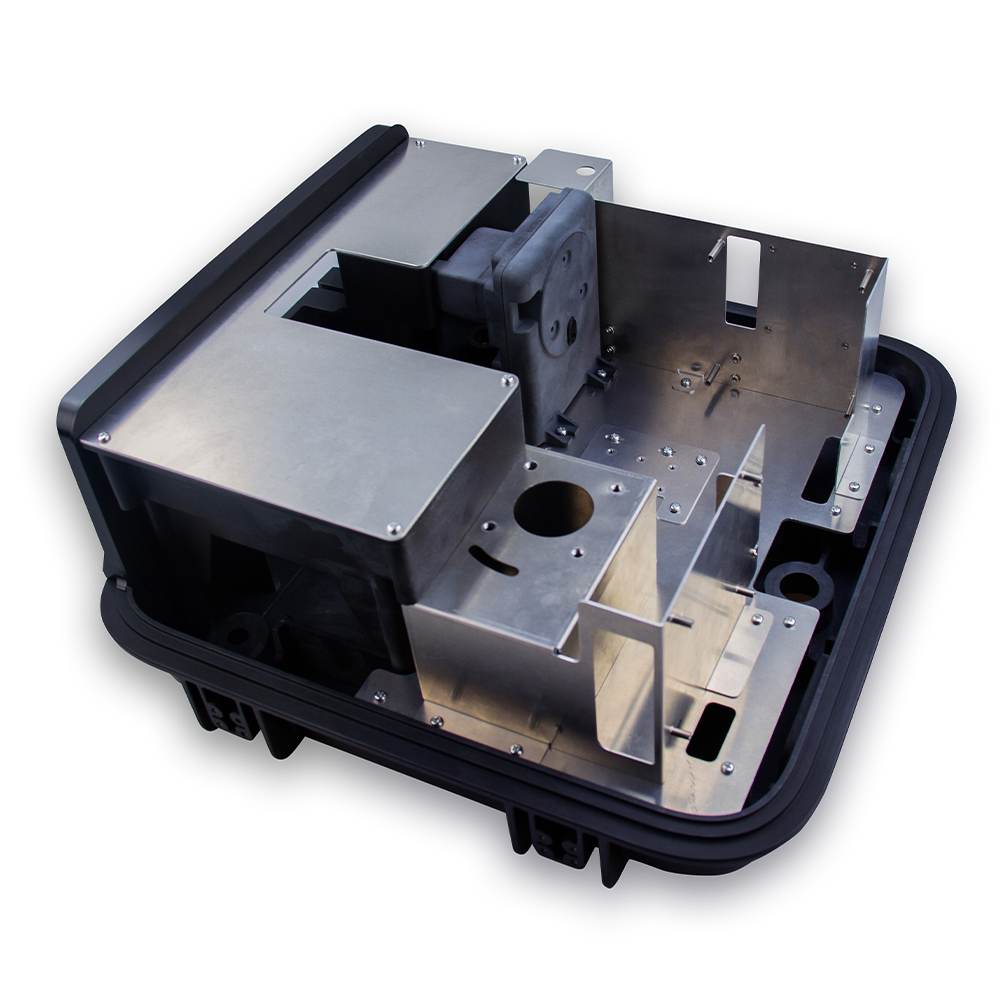

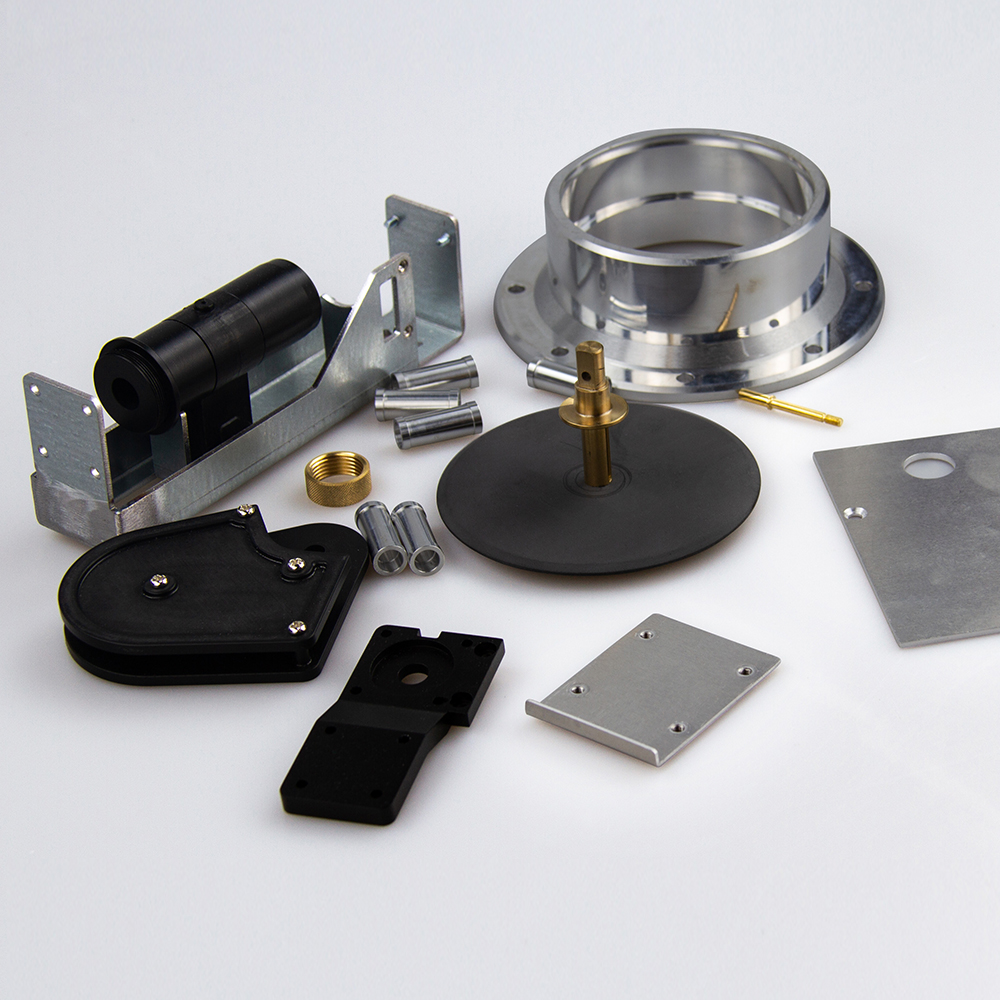

Many products rely on the use of metal sheets to make housings, brackets, mounting plates, and other accessories made of steel and aluminum. Includes bending, stamping, cutting standard metal for hand plates and small series production, and can be used in series or alone. Manufacture custom sheet metal parts, such as brackets, plates, frame arms, busbars, jigs, etc. Keyo can be customized from one piece.

Choose the advantages of Keo sheet metal customization

Customize sheet metal parts

A wide selection of materials, finishes and thicknesses to meet custom requirements and deliver your order on time

durability

Sheet metal can be formed into many shapes. It creates a very durable surface for prototyping or end use.

economy

Sheet metal light weight, high quality, high efficiency. Since low installation costs mean low prices, especially in large quantities, it is also very affordable.

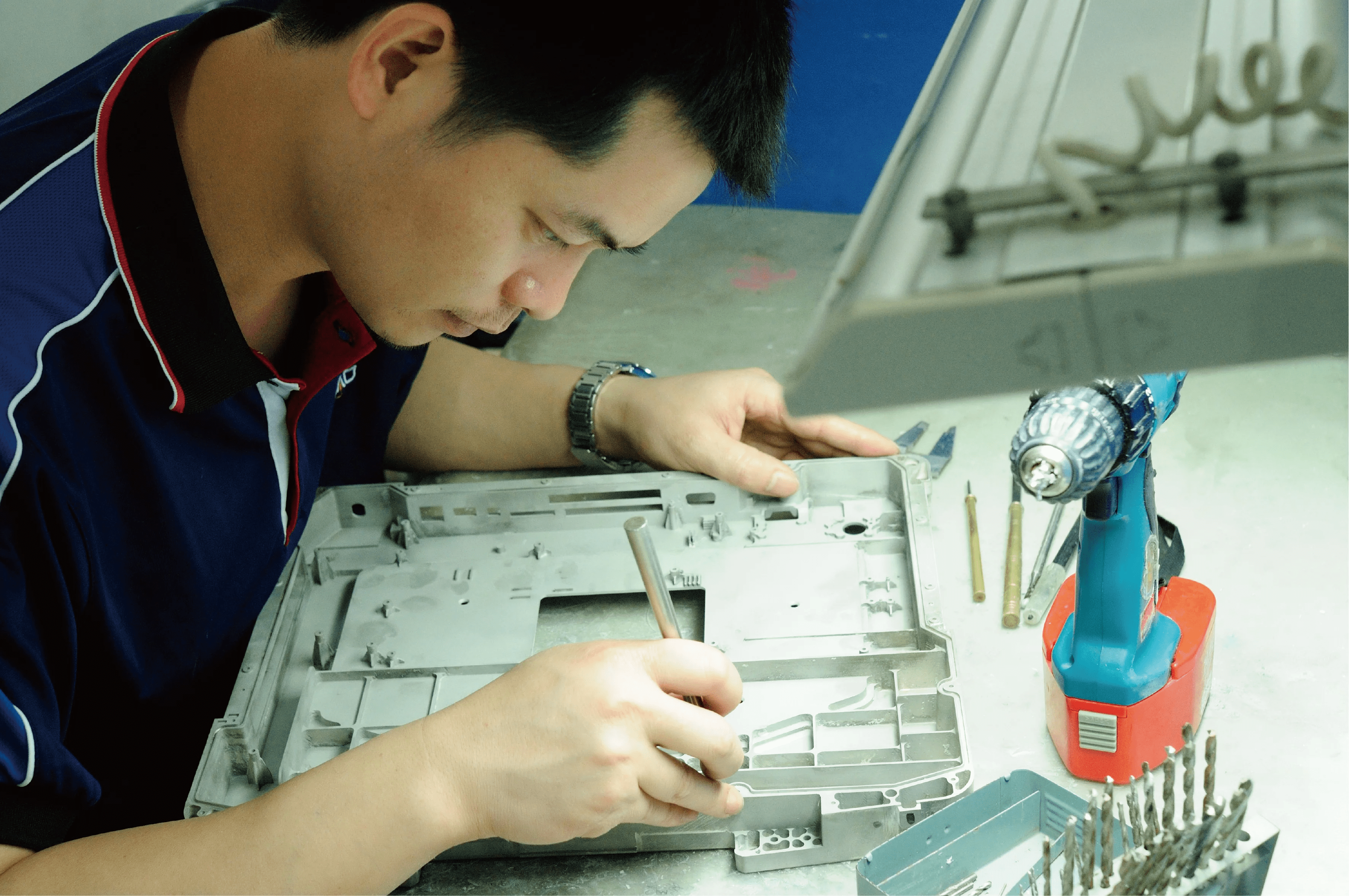

accuracy

Sheet metal projects can be completed using modern techniques. Sheet metal works well with an accurate measuring press.

Fast cycle

Fast turnaround of parts delivered within 4-10 days.

|  |

| bronze | Stainless steel | aluminum | copper | Cold-rolled sheet | Galvanized steel sheet |

| bronze220 | Stainless steel 301 | aluminum 6061 | copper101 | SECCcorporation | State Grid Corporation |

| bronze510 | Stainless steel304 | aluminum5052 | copperC110 | SECDcorporation | SGCEcorporation |

| Stainless steel 316/316L | copper 260 (Orichalcum) | SECEcorporation | SGCDcorporation |

Material options

| finishing | Sheet metal manufacturing finishing instructions from Keyo |

| Standard | Sheet metal manufacturing parts are reserved as manufactured parts. There will be visible mold marks on the parts. |

sandblast | A surface smoothing operation involving the orientation of fine glass beads on the surface of a part under high pressure. Sandblasting produces a smooth, even surface finish on the part. |

galvanize | Galvanizing is a type of galvanizing that involves applying a thin layer of zinc metal to the surface of another metal through a process called electrodeposition. |

Powder coating | Conductive gold parts can be coated with colored powder paint after manufacture to provide a dry, melted and hardened surface treatment. Ideal for workpieces that require textures that may not be possible with wet paint. |

Chrome plating | This involves depositing thin layers of chromium onto metal parts through an electroplating process. The chrome layer can play a decorative role, make the season anticorrosion or improve the surface hardness. Depending on the material and use of the end-use parts, a range of custom finishes are also available for your parts |

mores | Depending on the material and use of the end-use part, you can also offer a range of custom finishes for your part |

Join us

Apply for a position*

name*

Mobile phone number*

Wechat ID*

mailbox*

Consultation content*

Verification code

- I have read and agree 《Privacy protection agreement》