1/5

3D printing

产品详情

3D printing Services

As one of the earliest national rapid prototyping service centers in China, Keyo has accumulated rich experience in laser molding, using the laser forming machine of 3D SYSTEMS and the photosensitive resin RenShape SL7810 provided by HUNTSMAN, with the production accuracy up to ±0.1mm.

Advantages of 3D printing

Custom 3D printing accurate to CAD

Fast processing time and low cost

Production with the required materials without mold costs

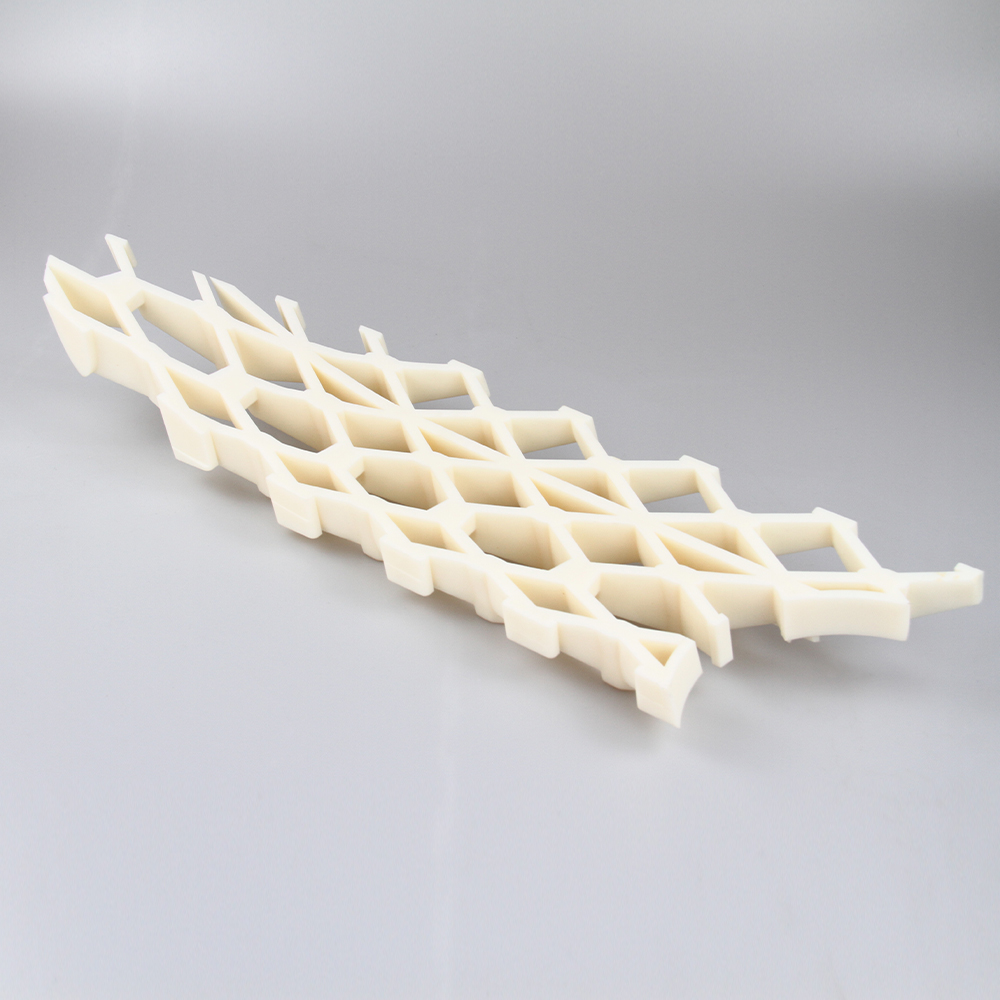

3D printing can achieve complex geometric shapes

SLA and SLS provide good surface finish

High precision can be used directly

Different types of 3D printing technology and how to choose

All the 3D CAD files you wish to print must be provided for the design and reviewed by the production team so that they can be optimized and crafted to meet the design requirements. Keyo offers a range of high-quality 3D printing services including FDM, SLA, SLS and SLM. This allows for 3D printing of plastics and metals, and provides options for handboard making and production

Difference between SLA and SLS

| Technology | Materials | Maximum part size | Mini feature size | Allowance |

| Stereolithography | Resin 8119 / Resin 8118H/ Resin 8228 | 29 inches by 25 inches by 21 inches | 0.025 inch | ±0.02 inches |

| Photoselective excitation sintering | Nylon/titanium/aluminum/stainless steel/cobalt/nickel/precious metal | 19 inches by 19 inches by 17 inches | 0.030 inch | ±0.01 inches |

3D printing service surface treatment

At Keyo, our high-quality 3D printed parts can provide protection, improve surface texture and enhance appearance through any one or a combination of the following processes

| Surface treatment options | 3D printing service surface treatment instructions |

| Standard | The 3D printed parts are sandblasted to remove the remaining powder. The surface finish is similar to the grain/crystal structure of sugar cubes. |

| Sandblast | A surface smoothing operation relates to the orientation of fine boscallops on the surface of a part under high pressure. Sandblasting creates a smooth, even surface finish on the part. |

| Transparent coating | Clear coating is a popular beauty procedure used to create a clear beauty appearance in 3D printed parts. |

| Painting | After grinding and polishing to make the surface smooth, the 3D printed parts can be covered with automotive quality paint and sprayed in any color. |

| Polishing | Used to create high quality surface finish in 3D printed parts. Before polishing, the parts should be polished and smoothed to ensure that the final surface appearance and cost meet expectations |

| Texture | Texture helps enhance ergonomics, cosmetics and weather resistance. It uses thousands to give 3D printed parts a better grip, reduce their slip, and mimic certain textures |

| Mores | Depending on the material and use of the end-use pieces, you can also offer a range of custom finishes for your pieces. |

Why choose Kaio CNC Machining Services?

Leading CNC equipment and materials

Our imported 5-axis CNC machining centers manufacture turning and milling parts using a variety of plastic and metal alloy materials such as aluminum, brass, nickel and steel, including mild steel and stainless steel. We use industry-leading software such as Autodesk PowerMill and CGTech Vericut, and we have over 14,000 tools.

Hand plate processing rich experience guidance

We are proud to talk about the experience and performance of our team, and one of the best ways to demonstrate the advantages of our CNC machining services is with our customers, 90% of whom are long-term partners. Our specialist technicians serve the entire process - from the initial stages of product design, helping with material selection, to manufacturing the first prototype, to the final production run.

Complete testing equipment

In order to ensure high quality products to customers, the company is equipped with a full set of quality testing equipment: three-dimensional testing, surface measuring instrument, height gauge, paint surface resistance instrument, micrometer, color difference detector, hardness tester, etc., by professional testing personnel.

3D printing FAQ

In order to ensure high quality products to customers, the company is equipped with a full set of quality testing equipment: three-dimensional testing, surface measuring instrument, height gauge, paint surface resistance instrument, micrometer, color difference detector, hardness tester, etc., by professional testing personnel.

A variety of 3D printing technologies are available

Our 3D printing service includes six 3D printing technologies that convert your 3D files into plastic, metal and elastomer parts. With more than 120 3D printers, we have unparalleled capacity to reliably deliver parts in a matter of days.

Join us

Apply for a position*

name*

Mobile phone number*

Wechat ID*

mailbox*

Consultation content*

Verification code

- I have read and agree 《Privacy protection agreement》