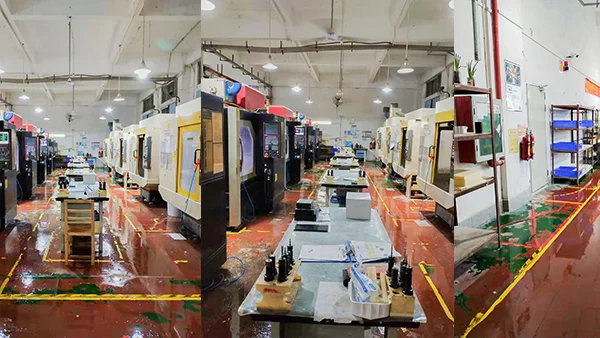

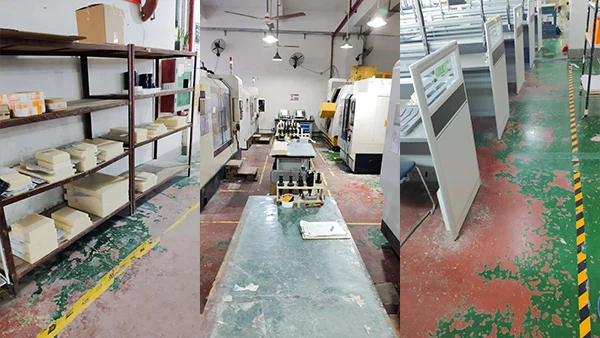

Manual sample small batch production factory 5S cleaning

Busy production department (CNC machining, RIM low pressure injection molding, reaction injection molding, silicone laminate, spray painting group, grinding group, sandblasting group, manual group, fast sample group, hand sample, sheet metal processing department) partners did a beautiful thing, look, the workshop floor was dragged spotless, the work surface clean up neatly, All the clutter that had been piling up in the nooks and crannies was cleared away. To tell the truth, when I saw these photos in the company's wechat group yesterday, I thought that the company was about to come to the factory inspection of big customers again. After a closer look at the content, it turned out that it was the 5S cleaning activity jointly organized by the administration department and the production department. Last month, the manual team won the excellence award and the company awarded a box of oranges. And the 5S activity is not only this time, we will incorporate the 5S plan into our daily work in the future, so that our working environment will always be clean, tidy and hygienic. You see, the floor has been ground to a red and a green, and half of the new coat of surface paint has been removed, which is enough to prove that time has left deep traces in every corner of Kaio. I believe that with the serious efforts of every partner of Kaio, The quality of carefully carved hand samples and small batch production products will be consistently good. Remember the company culture of "striving for perfection, exceeding customer expectations and exploring new solutions".